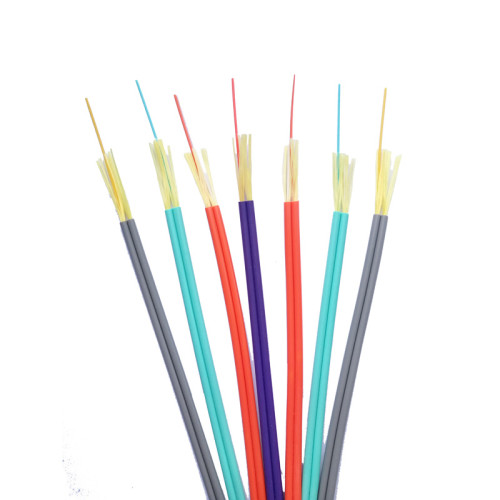

Zipcord Interconnect Cable Indoor distribution cable G657B3 LSZH Tight buffer fiber cable

- Model

- GJFJBV(H)

Item specifics

- Fiber Type

- SM, OM1, OM2, OM3, OM4, OM5

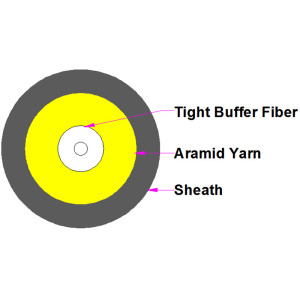

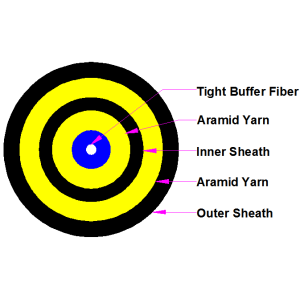

- Fiber

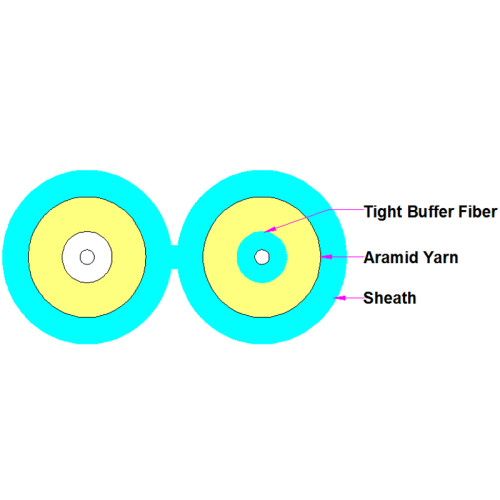

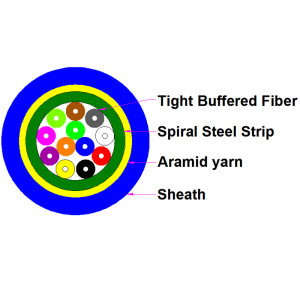

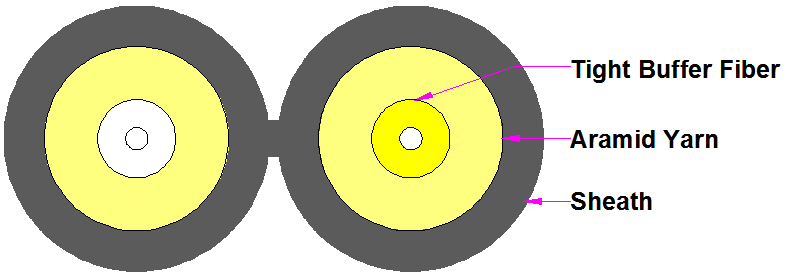

- Tight Buffer fibre (easy strip or difficult)

- Strength Member

- Aramid yarn (Excellent tensile strength)

- Outer Sheath

- LSZH/PVC (anti-corrosion,anti-water,anti-ultraviolet radiation, flame-retardant

- Cable Diameter (mm)

- 3.4*1.6, 4.0*1.9,5.8*2.8

- Cable Weight (kg/km)

- 4.8-14.8

- Crush Resistance (Long term N/100mm)

- 100

- Crush Resistance (Short term N/100mm)

- 500

- Application

- Duplex Optical Fibre Jumper or Pigtail

- Standards

- YD/T1258.2,

Review

Description

1.2 Characteristics

A. Tight buffer fiber easystrip

B. Tight buffer fiber has excellent flame-retardant performance

C. Aramid yarn as strengthmember make cable have excellent tensile strength

D. The jacketanti-corrosion, anti-water, anti-ultraviolet radiation, flame-retardant andharmless to environment etc.

1.3 Cable Application

A. Optical fiber jumper or pigtail

B. Indoor riser level andplenum level cable distribution

C. Interconnect betweeninstruments, communication equipment.

1.4 CableProperties

Transporttemperature: - 20 deg C to + 60 deg C

Storage Temperature: - 20 deg C to + 60 deg C

Operating temperature: - 20 deg C to + 60 deg C

Installation temperature: - 5 deg C to + 50 deg C

2. Optical Characteristics& Technical Parameters

2.1 Technical Parameters

|

Cable Code

|

Cable Diameter

mm |

Cable Weight(Ref) kg/km | TBF Diameter μm | Tensile strength Long/Short term mm |

Crush Resistance

Long/short term N/100mm |

Bending Radius

Dynamic/Static mm |

|

PVC jacket | LSZH jacket |

||||||

|

GJFJBV(H)-1.6

|

3.4x1.6

|

4.8 | 5.3 | 600±50 | 40/80 |

100/500

|

60/30

|

|

GJFJBV(H)-1.9

|

4.0x1.9

|

8.0 | 8.7 | 900±50 | 100/200 |

100/500

|

60/30

|

GJFJBV(H)-2.8 | 5.8x2.8 | 11.6 | 14.8 | 900±50 | 100/200 | 100/500 | 60/30 |

Fiber Type |

Attenuation |

OFL | Valid mode band width |

10G Ethernet link length SX |

Min. bending radius | |||

Condition | 1310/1550nm | 850/1300nm |

850/1300nm | 850nm | 850nm | |||

|

Typical

|

Max. | Typical | Max. |

|

|

|||

|

Unit

|

dB/km

|

dB/km | dB/km | dB/km | MHZ.km |

MHZ.km

|

m

|

mm |

G652D | 0.36/0.22 | 0.5/0.4 | 16 | |||||

G657A1 | 0.36/0.22 | 0.5/0.4 | 10 | |||||

G657A2 | 0.36/0.22 | 0.5/0.4 | 7.5 | |||||

OM1 | 3.0/1.0 | 3.5/1.5 | ≥500/500 | ≥2000 | ≤300 | 30 | ||

OM2 | 3.0/1.0 | 3.5/1.5 | ≥200/500 | ≥4700 | ≤550 | 30 | ||

OM3 | 3.0/1.0 | 3.5/1.5 | ≥1500/500 | ≥2000 | ≤300 | 30 | ||

OM4 | 3.0/1.0 | 3.5/1.5 | ≥3500/500 | ≥4700 | ≤350 | 30 | ||

3. Packing and shipping

3.1 The cables are packed in wooden drums andthen in carton box

3.2 Standard delivery length is 1km/roll or percustomer’s requirements.

3.3 Sheath Marking

The sheath marking are hotstamped on the sheath at one meter interval with white color. The accuracy ofthe length marking shall be 0 ~ +1%.

Re-marking is yellow color, ifnecessary.

RUX *** xxFIBRE Month/Year XXXXM

l RUX: Manufacturer’s Name

l ***: Customer’s name

l xxFIBRE: Fiber count

l Month/Year: Manufacturedate

l XXXXM: The figure of meter.