Air-blown Micro cable GCYFY12~ 144 Fiber

- Model

- GCYFY12~ 144

Item specifics

- Brand Name

- RUX

- Place of Origin

- Guangdong, China (Mainland)

- Fiber Type

- SM G657A/G652D

- Loose tube material

- PBT

- Strength Member

- FRP

- Fiber Count

- 2-144 cores

- Outer Sheath

- Black Polythene (PE) Jacket

- Temperature range

- -40°~60°C

- Delivery Time

- 10-15 days

- Package

- 2 km/ spool

Review

Description

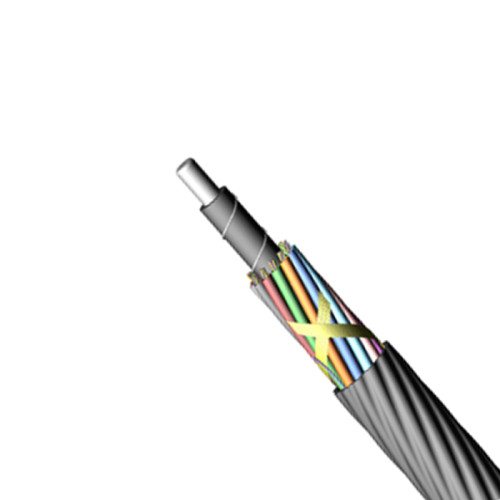

1.1 Cable Description(Air-blown Micro cable)

12/24/36/48//72/96/144 G.657A2SM-fibers.

Loose tubes SZ-stranded.

Suitable for air blown cable in micro-ductinstallation.

1.2 Reference

|

ITU-T G.657A2

|

Characteristics of a single-mode optical fiber

|

|

IEC 60794-1-1

|

Optical fiber cables- part1-1-Generic specification-General

|

|

IEC 60794-1-2

|

Optical fiber cables- part1-2-Generic specification-Basic optical cable test procedure

|

|

IEC 60794-3

|

Optical fiber cables- part3-Sectional specification- Outdoor cables

|

IEC 60794-5 | Optical fiber cables- part5-Sectional specification- Microduct cabling for installation by blowing |

1.3 Working Condition

Transportation and storage temperature:-40℃~+70℃

Installation temperature: -15℃~+60℃

Operation temperature: -20℃~+70℃

1.4 Minimum Allowable Bending Radius

Static: 10D

Dynamic: 20D

D is the out diameter of the cable

2. Optical Fiber In Cable(ITU-G657A2)

Optical properties of the SM fiber areachieved through a germanium doped silica based core with a pure silicacladding which meets ITU-T G657A2, UV curable acrylate protective coating isapplied over the glass cladding to provide the necessary maximum fiberlifetime.

Geometrical, optical, and mechanicalcharacteristics of fiber in cable as the following table:

|

Category

|

Description

|

Specification

|

|

|

Before cable

|

After cable

|

||

Geometrical Characteristics | Cladding diameter | 125.0 ± 1 mm | |

Cladding non-circularity | ≤1.0 % | ||

Core concentricity error | ≤ 0.6mm | ||

Coating diameter | 245± 10 mm(Before Colored) 250 ± 15 mm (Colored) | ||

Coating/cladding concentricity error | ≤ 12mm | ||

Optical Characteristics | Mode field diameter at 1310 nm | 9.2 ± 0.4 mm | |

|

Point discontinuity

|

≤ 0.05dB

|

||

|

Attenuation at 1310 nm

|

≤ 0.34 dB/km

|

≤ 0.35 dB/km

|

|

Attenuation at 1383 nm | ≤ 0.34 dB/km | ≤ 0.35 dB/km | |

Attenuation at 1550 nm | ≤ 0.21 dB/km | ≤ 0.22dB/km | |

Attenuation at 1625 nm | ≤ 0.23 dB/km | ≤ 0.24dB/km | |

Dispersion in 1288 – 1339 nm | ≤ 3.5 ps/(nm·km) | ||

Dispersion in 1271 – 1360 nm | ≤ 5.3 ps/(nm·km) | ||

Dispersion at 1550 nm | ≤ 18 ps/(nm·km) | ||

Zero dispersion wavelength | 1300 – 1324 nm | ||

Zero dispersion slope | ≤ 0.092 ps/(nm2·km) | ||

Cable cut-off wavelength | ≤ 1260 nm | ||

Polarization mode dispersion individual fiber | ≤ 0.2 ps/Ökm | ||

Polarization mode dispersion design link value (M=20, Q=0.01%) | ≤ 0.1 ps/Ökm | ||

Macro-bend loss (100 turns, 30mm radius, 1550/1625nm) | ≤ 0.1 dB | ||

Mechanical Specification | Proof stress level | ≥100kpsi (0.69 GPa) | |

Coating strip force(peak value) | 1.3~8.9N | ||

Fiber curl (Radius) | ≥4 m | ||

3. OpticCable

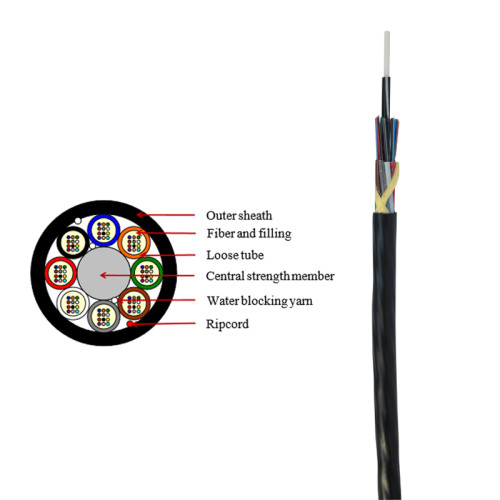

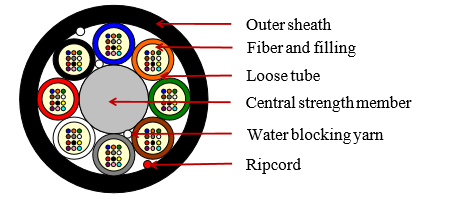

3.1 General Design

Optical fibers are housed in loose tubes that are made ofhigh-modulus plastic and filled with waterproof compounds.

FRP is applied as central strength member.

Loose tubes are SZ-stranded around the strength member.

Water blocking yarns are used in and over the cable core toprevent it from water ingress. Polyethylene sheath is applied over the cablecore as the outer sheath.

3.2 Construction

3.2.1 Dimensions and Descriptions of Cable Constructions

|

Item

|

contents

|

Value

|

||||||

|

12

|

24

|

36 | 48 | 72 | 96 | 144 | ||

|

Loose tube

|

Number

|

1

|

2

|

3 | 4 | 6 | 8 | 12 |

|

Outer diameter (mm)

|

1.5

|

|||||||

Filler | Number | 5 | 4 | 3 | 2 | 0 | 0 | 0 |

3.2.2 Mechanical Performance of Cable

|

Tensile performance(N)

|

Crush(N/100mm)

|

||

|

Short term

|

Long term

|

Short term

|

Long term

|

|

0.5*G

|

0.15*G

|

450

|

150

|

3.3 Mechanical, Electrical andEnvironmental Test Characteristics

The finished cables can be subjectedto the following mechanical, electrical and environmental conditions.

|

Item

|

Test Method

|

Requirements

|

|

Tensile

|

IEC 60794-1-2-E1

|

The maximum increase in attenuation less

|

|

performance

|

Load: according to short term tensile described in 3.2.3

Cable length under tension: Not less than 50m. Duration of load sustain: 1min. Velocity of transfer device: 10mm/min |

than 0.1dB.

The maximum fiber strain less than 0.3% under maximum tensile short term load. No change in attenuation after test at 1550nm. Under visual examination without magnification, no damage to the sheath or to the cable elements after test. |

|

Crush

|

IEC 60794-1-2-E3

Load: 450N Duration of load: 1min |

No change in attenuation after test at 1550nm. Under visual examination without magnification, no damage to the sheath or to the cable elements. The imprint of the striking surface on the sheath is not considered mechanical damage.

|

Bend | IEC 60794-1-2-E11A diameter Turns:10 Cycles:5 | No change in attenuation at 1550nm after test. Under visual examination without magnification, no damage to the sheath or to the cable elements. |

Repeated bending | IEC 60794-1-2-E6 Bending radius: 20 times cable diameter Cycles: 25 Load: 25N Duration of cycle: Approximately 2s. | No change in attenuation at 1550nm after test. Under visual examination without magnification, no damage to the sheath or to the cable elements. |

Torsion | IEC 60794-1-2-E7 Cycles:5 Length under test: 1m Turns: ±180° Load: 40N | The variation on attenuation for each fiber less than 0.05dB at 1550nm Under visual examination without magnification, no damage to the sheath or to the cable elements. No permanent change in attenuation after test |

Temperature cycling | IEC 60794-1-2-F1 Sample length: at least 1000m Temperature range: -20℃~+70℃ Cycles: 2 Temperature cycling test dwell time: 12 hours | There is no change in attenuation coefficient at 1550nm after the test. |

Water Penetration | IEC 60794-1-2-F5B Time : 24 hours Sample length : 3m Water height : 1m | No water leakage |

Compound flow | IEC 60794-1-2-E14 Sample count:5 Sample length:300 ±5 mm, Remove length: 130 ±2,5 mm, Time:24h | No filling compound dripped. |

Other parameters | According to IEC 60794 ,YD/T 1460.4-2006 | |

Remark: “No attenuation changes” is considered as the attenuationchanges ≤ 0.05 dB.

4. Cable SheathMarking

Unless otherwise specified, the cable sheath marking shall be asfollows:

Ø Color: white

Ø Contents: the year of manufacture,the type of cable, length marking

Ø Interval: 1m